Startseite

Our

prototype lab

for your ideas

Are you a founder or part of a start-up and want to bring your product to market quickly and efficiently? We support you in transforming your innovative ideas into marketable products. Our expertise in cabling and assembly ensures that your devices function reliably and optimally.

We offer:

- Practical support: We take over the development and production of the cabling for your products so that you can concentrate on the essentials – innovation.

-

- Efficiency: Our optimized processes accelerate your product development and help you get to market faster.

Let’s bring your ideas to life together and shape the future. Contact us today and find out how we can support you and your company or come and see us directly with your mock-up!

That worked out perfectly...

RAYSRIDE with their plattform solution

Raysride has developed a new type of four-wheeled CargoBike platform made of sheet metal. The four-wheeled platform has an adaptable vehicle and self-propelled trailer – cabins, luggage compartments and other superstructures can be freely configured. The pedelec version enables the use of cycle paths and parking lots anywhere.

Challenge

Sheet metal forming is raysride's core business. It was clear that an AES battery would supply the future vehicle with energy, but it was not yet clear how this would reach the individual consumers. In particular, the selection of the right plug connections, the routing and mechanical protection of lines, cables and strands was the next milestone and therefore a challenge for the company.

Solution

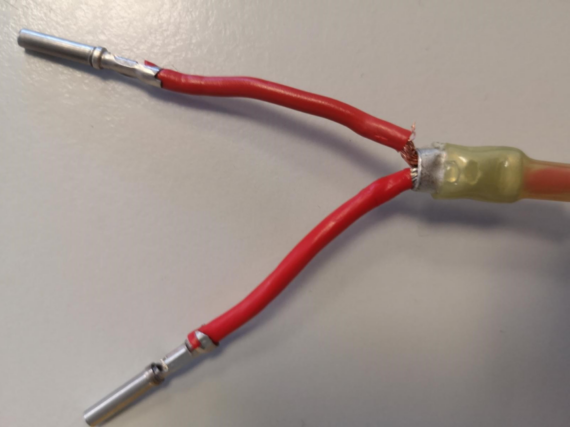

In addition to the production of the required AKKU cables, the colleagues from Jürgenhake also provided raysride with advice and support on the subject of vehicle cabling. From the selection of the individual components to the optimum arrangement of the strands in a wiring harness, the team received valuable information that raysride incorporated into the development in the best possible way. In addition to providing technical support in their area of expertise, Jürgenhake also put them in touch with important network partners who also shared their specialist knowledge with raysride.

Realization

In several telephone calls and on-site meetings, the colleagues from Jürgenhake described what data they needed for the production of the cable harnesses. Together, they defined all the interfaces and the connections between them and selected the appropriate components. The discussions and deliberations about the advantages and disadvantages of the various components will live long in the memory.

Hopper Mobility GmbH with their Hopper

With the HOPPER, the ideal city vehicle is developed and produced:

Challenge

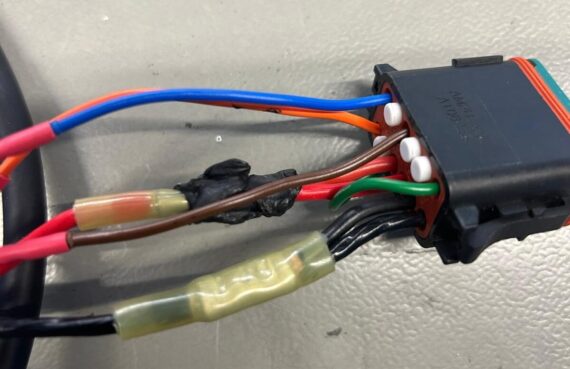

Hopper is currently taking the step from the pilot phase to series production. This requires an increase in quality and reliability in all areas. A well-designed and reliable wiring harness is essential as a neural network between all electronic components in order to enable all essential vehicle functions. In addition to the routing in the vehicle and the wiring in general, the correct design and consideration of various safety standards are among the numerous topics we deal with in order to make the wiring harness ready for series production.

Solution

Collaboration with experts on all aspects of a wire harness - from the joint definition of individual plug connections and wire harness wiring to documentation to ensure quality - is essential for us.

Realization

Jürgenhake offers full support here. After providing an early prototype, Jürgenhake develops the wiring harness directly on the vehicle, taking reliability and product costs into account. This was followed by iterative optimizations during the pilot phase and finally the finalization of the wiring harness on the pre-series vehicle.

MOTIC with their Cargobeast

The Cargobeast is THE innovative e-cargo bike that offers the advantages of a small truck in a format suitable for cycle paths. Whether for the last mile, internal logistics or the safe transportation of sensitive goods: it is powerful, manoeuvrable and robust. With modular superstructures and scalable ranges, the Cargobeast adapts perfectly to your company.

Challenge

The Cargobeast offers various loading spaces, including a lowerable loading area and insulated superstructures with a cooling function. A major challenge was to develop a reliable overall system with the existing systems available on the market. A completely new wiring system had to be developed for this purpose.

Solution

Thanks to our expertise in the area of pre-development and our hands-on mentality in finding solutions, we were able to develop a tailor-made solution for the Cargobeast in a short space of time - supported by the targeted use of standard components and our experience in the development and production of battery-electric drivetrains.

Realization

The pre-development and production of initial samples based on sketches and ideas as well as the direct implementation of these designs, including the installation of components in our Mock-Up Lab, enable us to test and optimize practical solutions quickly and flexibly.

If the following “highlights” sound familiar to you, we should talk!

Was that already

on your agenda?

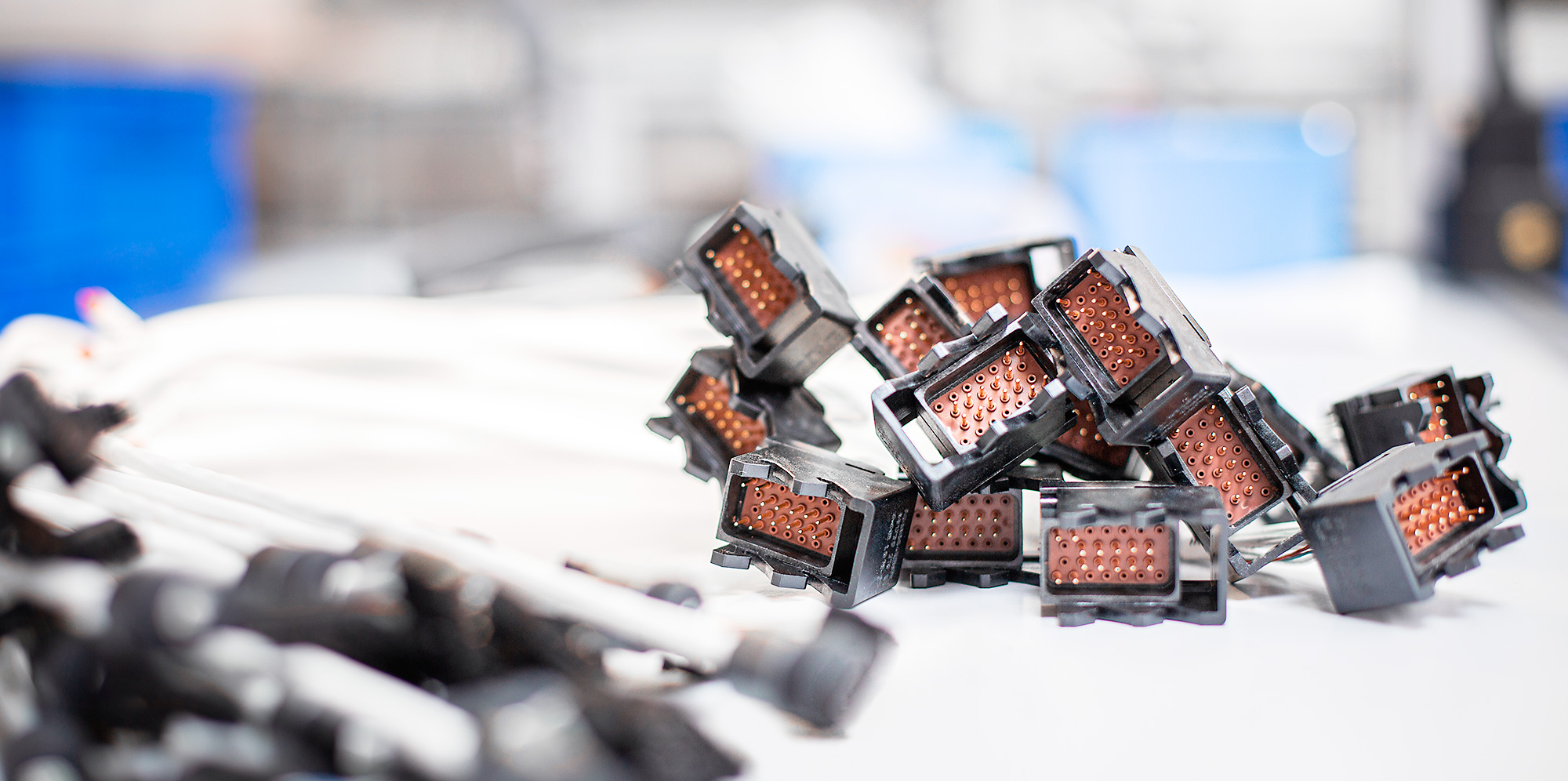

- Cable assembly is much more than just connecting cables – it is precision work that offers tailor-made solutions for complex requirements.

- Every cable harness is designed and tailored precisely to your requirements.

- Professional cable harnesses ensure stable connections with a high load capacity for you and your customers.

- You have less downtime and more efficient assembly thanks to sophisticated and modular cable systems.

- To scale up quickly from prototype to series production, you need perfectly coordinated solutions and professional components for your requirements.

- With the right partner, you can turn your ideas into reality – from the initial concept to the professional product!